Pacific Dynamics Cabinetry

Pacific Dynamics Cabinetry can create cabinets for anyone! Whether you are a homeowner or a contractor, we can help create the perfect solution for your project. We have the experience and ability to create cabinets to specification or even help you with those specifications to make sure you get the perfect set of cabinets.

Already have an installer? No problem. We will work with you and your professional to deliver the cabinets you need. If you need someone to install them, we have professional installation services available to you. Simply use the contact form in the page below and get in touch with us to begin the process.

Select one of the galleries below, or scroll down to read more about our standards and the cabinet-building process here at Pacific Dynamics Cabinets.

We Ony Use Lumber That has Been Treated for Termites

One of the biggest problems in Hawaii are the bugs. While no wood is completely bug proof, there are certain precautions that should be taken to insure your cabinets are not attractive to bugs. One of those is using treated lumber. We do that at Pacific Dynamics in Kailua.

SoyStrong is a Formaldehyde-Free Soy-Based Adhesive

Soy-strong plywood is a new product that uses soy-based adhesives instead of formaldehyde resins in making the plywood. Pacific Dynamics is very sensitive about the use of chemicals and non-natural products used in our cabinets and will use alternatives whenever possible. Additionally, we use a safe method to introduce a natural insecticide additive into our glue line. The addditive molecules are surrounded by a polymeric wall that initially protects them from the outside environment. During the pressing process the heat and pressure rupture the capsule wall and enable the additive to be mixed with the wood fiber.

Cabinet Fabrication

All of our case work is done using maple 3/4" pre-finished maple plywood. It comes from Oregon and is treated for bugs in the fabrication, has soy-based adhesives instead of formaldehyde resins, and is a great wood to build with here in Hawaii. Our cabinets all have 1/2" backs instead of 1/4"

Drawer Construction

Our drawers are all constructed with 1/2" pre-finished maple, and follow the same standards as our cabinets. The drawer sides and bottoms use 1/2" pre-finished plywood that is dadoed in to insure no sag over time. Our drawers are some of the strongest on the market. Just look how much weight they can withstand:

Pacific Dynamics Cabinetry can create cabinets for anyone! Whether you are a homeowner or a contractor, we can help create the perfect solution for your project. We have the experience and ability to create cabinets to specification or even help you with those specifications to make sure you get the perfect set of cabinets.

Already have an installer? No problem. We will work with you and your professional to deliver the cabinets you need. If you need someone to install them, we have professional installation services available to you. Simply use the contact form in the page below and get in touch with us to begin the process.

Select one of the galleries below, or scroll down to read more about our standards and the cabinet-building process here at Pacific Dynamics Cabinets.

We Ony Use Lumber That has Been Treated for Termites

One of the biggest problems in Hawaii are the bugs. While no wood is completely bug proof, there are certain precautions that should be taken to ensure your cabinets are not attractive to bugs. One of those is using treated lumber. We do that at Pacific Dynamics in Kailua.

SoyStrong is a Formaldehyde-Free Soy-Based Adhesive

Soy-strong plywood is a new product that uses soy-based adhesives instead of formaldehyde resins in making the plywood. Pacific Dynamics is very sensitive about the use of chemicals and non-natural products used in our cabinets and will use alternatives whenever possible. Additionally, we use a safe method to introduce a natural insecticide additive into our glue line. The addditive molecules are surrounded by a polymeric wall that initially protects them from the outside environment. During the pressing process the heat and pressure rupture the capsule wall and enable the additive to be mixed with the wood fiber.

Cabinet Fabrication

All of our case work is done using maple 3/4" pre-finished maple plywood. It comes from Oregon and is treated for bugs in the fabrication, has soy-based adhesives instead of formaldehyde resins, and is a great wood to build with here in Hawaii. Our cabinets all have 1/2" backs instead of 1/4"

Drawer Construction

Our drawers are all constructed with 1/2" pre-finished maple, and follow the same standards as our cabinets. The drawer sides and bottoms use 1/2" pre-finished plywood that is dadoed in to insure no sag over time. Our drawers are some of the strongest on the market. Just look how much weight they can withstand:

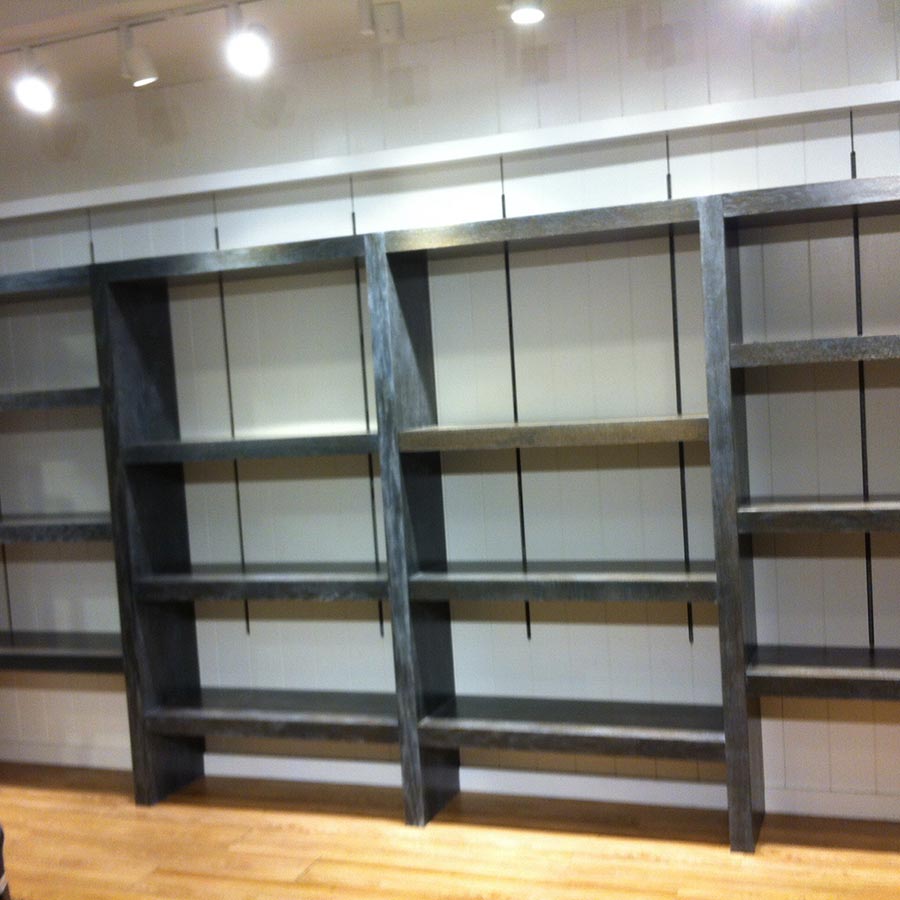

Our Commercial Projects:

We can create a number of different commercial solutions for you and your business. From functional cabinets that are used for storage or supplies, to beautiful, attractive creations meant to showcase your products or be placed in an area for your customers. All of our commercial cabinets are created with the same materials and with the same methods to deliver years of worry-free use.Our Residential Cabinet Gallery

Our Commercial Gallery

Lic.# BC7342 | 808.261.1615